How the University is driving change to reduce, reuse and recycle

Header image

Standfirst

It’s no surprise that the fashion industry is one of the most polluting industries in the world from its production, transportation, and consumption of clothing.

Contributing to a staggering 10% of global carbon emissions, according to the United Nations, it’s a sector where the overconsumption of the latest trends is driving the problem.

And in the UK alone, an estimated £140m worth of clothing is sent to UK landfill each year.

Main story

Making society more sustainable

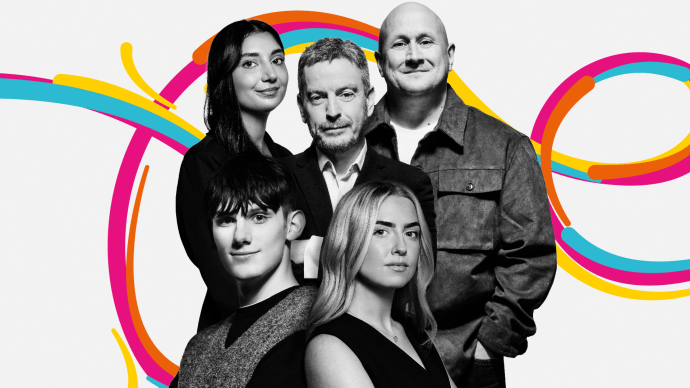

As the industry wakes up to the impact of climate change, Manchester Met’s Manchester Fashion Institute (MFI), one of the largest fashion schools in the UK, is leading the way to reduce, reuse and recycle – the circular economy.

It’s a challenge that been taken up elsewhere in the University: how we can make society more sustainable. From Manchester Met’s 3D printing hub PrintCity to business support projects helping small and medium-sized enterprises to adapt to the future.

Clare McTurk, Sustainability Lead at MFI, explains that much of the mainstream focus on fashion sustainability is centred around product but at MFI the focus is more extensive.

By inspiring our students to not only do great things with products, but also understand sustainable processes we’ll be shaping change makers of the future.

“At MFI we are broadening our focus beyond product and embracing eco-friendly, ethical, and socially responsible methods in the design, production, marketing, and consumption of fashion to minimise environmental impact,” she said.

“Incorporating consumption in the curriculum is essential, as it addresses the demand side of the industry which drives production and waste. By inspiring our students to not only do great things with products, but also understand sustainable processes we’ll be shaping change makers of the future.”

Rethinking the hospital gown

And one Man Met fashion graduate is doing just that with her sustainable and functional hospital gown. Since graduating from BA (Hons) Fashion and Business Management in 2023, Olivia Burns has developed Hypoplas, an innovative patient wear brand inspired by her own patient experience. Working with Birmingham Children’s Hospital – where she was first treated – Burns said: “We found many hospitals were ‘double gowning’ where patients wear two gowns at once with one reversed to preserve modesty, meaning double the laundry and using double the carbon.

“To address this problem, I’ve designed a hospital gown that preserves the modesty of patients, is sustainable, and cost-effective for healthcare organisations.”

It’s the move to come up with innovative solutions that is driving progress in other areas of the University.

From waste plastic to 3D printing

PrintyCity has previously used its expertise with partners to turn waste plastic into new 3D printing filaments to be re-used in new products.

It is also part of a £1.5m project to sustainably upgrade water supply infrastructure, 3D scanning and supplying parts on demand for United Utilities, working with ChangeMaker 3D and Scottish Water.

Alan Dempsey, Project Manager for PrintCity at Manchester Met, said: “Working with Changemaker 3D, we will enable water companies to 3D print concrete and polymer parts when they are required. This will help them to reduce the reliance on the delivery of new equipment, improve the turnaround times for project delivery and take major steps forward in reducing costs, resources and impact on the environment.”

Pre-loved, make-do, and mend

Innovative research encompasses all areas of sustainability from supply chain, to changing consumer behaviour, to social justice, and it’s making real-world impact.

One example is Back to Baselines in Circular Fashion and Textiles, which aims to address the challenge of circularity – where fashion is renewed or regenerated, rather than wasted – in the UK fashion and textiles industry. Working in partnership with the Waste and Resources Action Programme (WRAP) and the University of Leeds, Professor Liz Barnes, head of MFI, is exploring how to influence consumer change and behaviour towards improved circularity and how this can be accelerated through initiatives like pre-loved fashion, or make-do and mend.

She will also explore how to influence organisational behaviour towards better circularity by looking at what policies, training, development, and guidance are needed.

Introducing the Robotics Living Lab

In Manchester Metropolitan’s Business School, SMEs are being supported to create new sustainable products. As part of £100m government funding, its Centre for Enterprise will support regional business, alongside other areas of the University, to adopt new hydrogen fuel, artificial intelligence, cyber, industrial digitalisation and immersive technologies.

While MFI will be launching the Robotics Living Lab (RoLL) next year, a new £4m fashion research hub using collaborative and soft robotics and agile tooling to support local and sustainable production.

Fashion researchers, designers, and manufacturers will collaborate with RoLL to use robotic technologies to create high-value, low-volume fashion. The low-carbon, timber and straw pavilion, designed by Bennetts Associates, will provide an adaptable workspace that can be used for exhibitions and events for RoLL to showcase its work and research.

There’s no doubt that research and education from the University is making a significant impact at a crucial time when positive changes are needed to achieve a more sustainable future.

More stories

Discover more of our research

-

![An aeroplane taking off, seen from inside an empty passenger lounge]()

Cleaner and greener flying

Find out more -

![A researcher operating one of the machines in the Manchester Fuel Cell Innovation Centre]()

The future of clean power

Find out more -

![Dr Paul O'Hare stood among wildflowers with Manchester post-industrial skyline behind him]()

Greening the city – Manchester’s changing climate

Find out more -

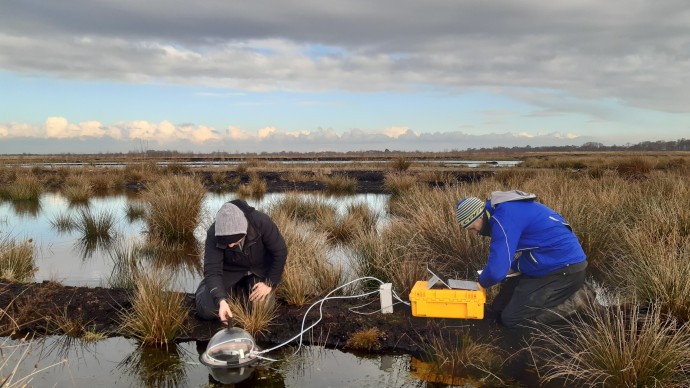

![Researchers taking measurements from a peat bog in the Peak District]()

A natural solution

Find out more -

![A Golden Parakeet with its wings spread in the air]()

All creatures great and small – protecting biodiversity

Find out more

About 200 years

Manchester Met celebrates two centuries of driving progress through excellent education and research.

-

![200 years 1824-2024]()

200 years

Find out more -

![Siemens Chief Executive Carl Ennis posing with the firms degree apprentices]()

Driving economic growth

Find out more -

![Two nurses standing together and smiling]()

Transforming health

Find out more -

![A digital image of the university's arts buildings]()

Championing creative excellence

Find out more